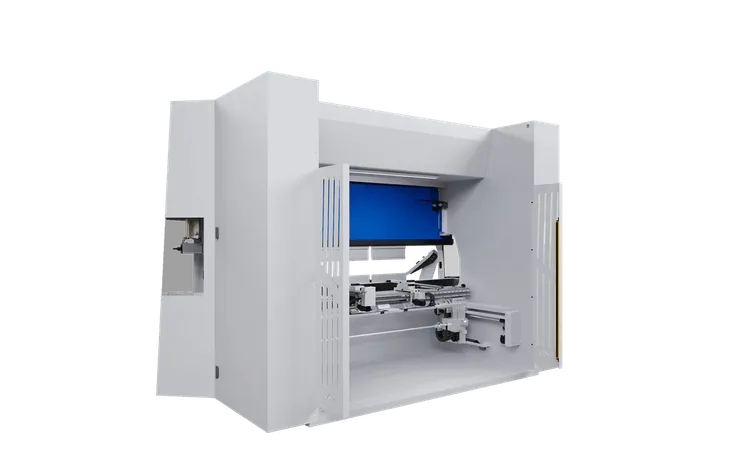

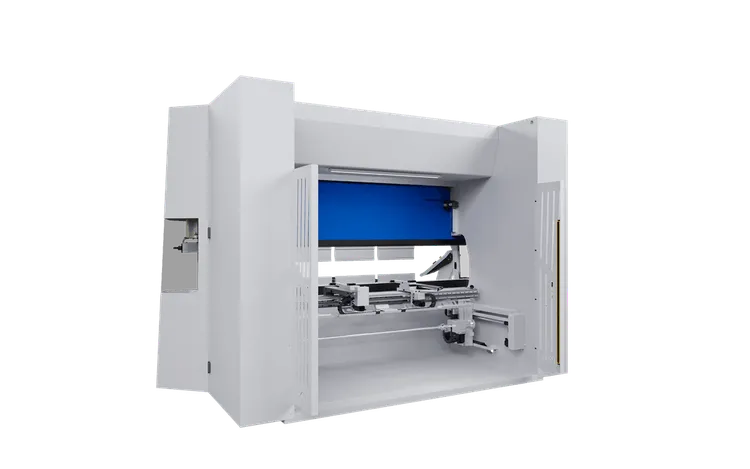

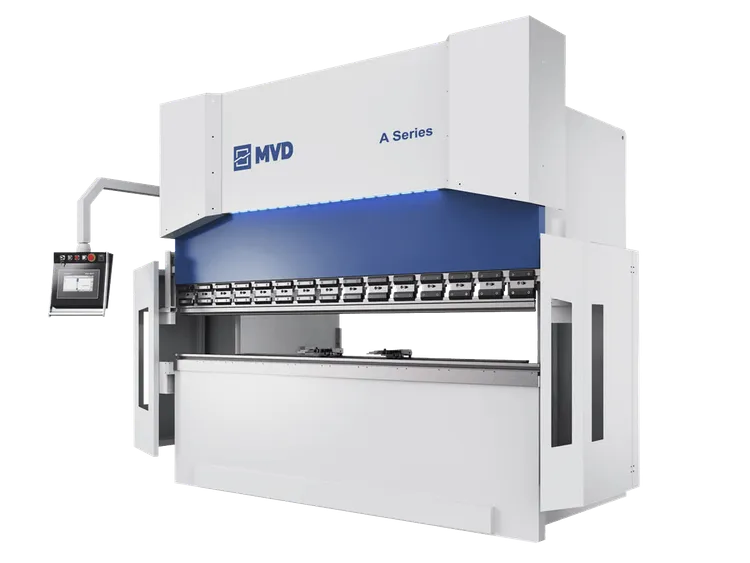

RICO PRCN-I Line CNC Hydraulic Synchronised Press Brake

Synchronised Hydraulic Multi Axis Press Brake

The RICO PRCN I line CNC Synchronised Hydraulic Multi Axis Press Brake is a 'premium' high performance

Hydraulic Synchronised Press Brake, with a 'UNIQUE STRUCTURE' for high precision sheet metal bending

or heavier steel plate bending.

RICO Brake Press structures are calculated to achieve minimal structural deflection during a metal bending cycle.

RICO uses only high-quality certified steels in a Press Brake structure to achieve minimal structural deflection

PRESS BRAKE

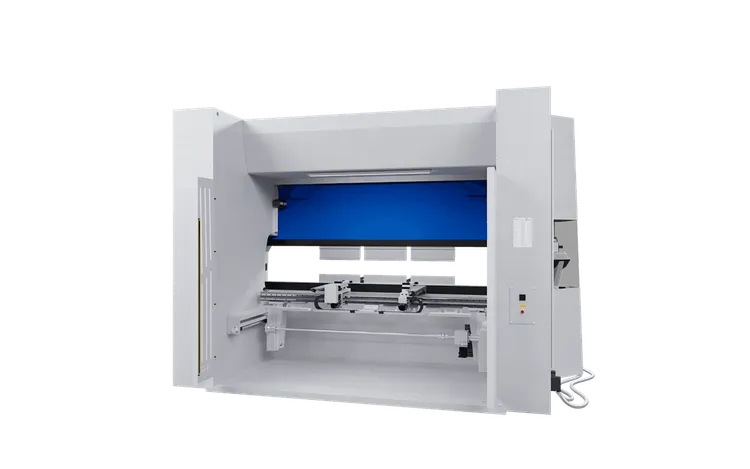

'Standard' RICO I Line Brake Press - Technical Specification

- Tonnage capacities 70 tons | 100 tons | 135 tons | 160 tons | 200 tons

For a higher Tonnage'range, see the RICO C Line Hydraulic Synchronized Brake Press - Bend Lengths 2100 mm | 2600 mm | 3100 mm | 3600 mm | 4100 mm

- Throat depth 310 mm or 410 mm (dependant on model)

- Daylight 500 / 520 mm (no tooling fitted)

- Beam Stroke 300 mm

- Standard 4 Automatic Axis [Y1+Y2+X+R]

- BGR Back gauge - Precise, robust box section

- Standard Controller DELEM DA-66T

- Hanging Swivel Machine Control

- Front Supports - SFS Sliding

- Frontal Operator Safety AKAS II-F

- Rear Entry Safety Barriers (Level IV)

- Promecam Style Top & Bottom tool clamping (Euro Style)

- Off Line Software - Profile TL

- All RICO machines have an integrated 'StandBy' function, which automatically

stops the machines motor after 5 mins if inactivity

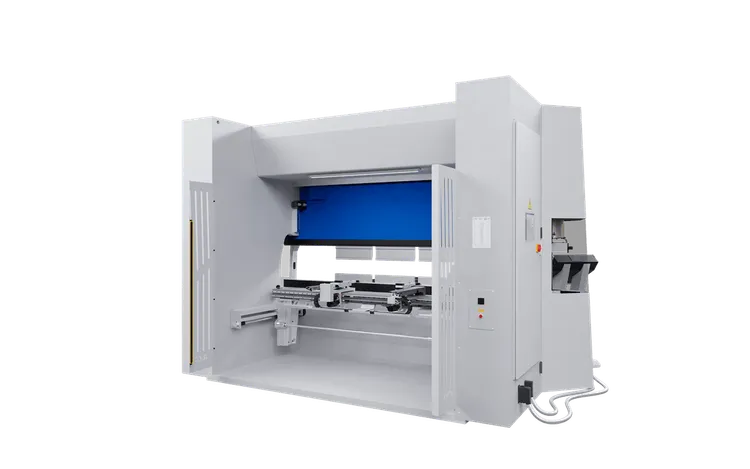

Extra 'Options'

- BGR - Additional Back Gauge Axis [Z1+Z2+X5]

- ECO Boost - Increases the beam return speed

- LED tool Locator, assists the operator position parts in complex bending programs

- BTM Back Gauge 6 Automatic Axis X1+X2+R1+R2+Z1+Z2

- BTL Back Gauge 6 Automatic Axis X1+X2+R1+R2+Z1+Z2

- 3D CNC Graphic controls

- Material Follower Supports ACFL | ACFA | ACF1 | ACF2

- Manual Quick Clamping | Pneumatic | Hydraulic clamping systems

- Tandem or Tridem capacities - 800 tons x 12000 Bend length